Codice Articolo 400030

Da casa Serpent Project 4x Touring Car 1/10 EP versione in kit.

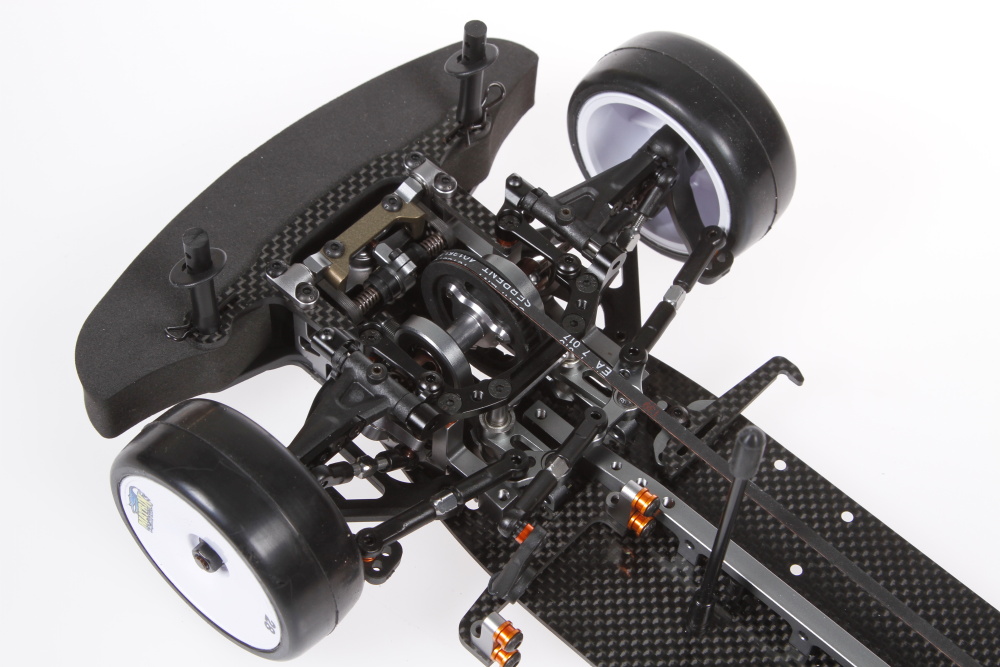

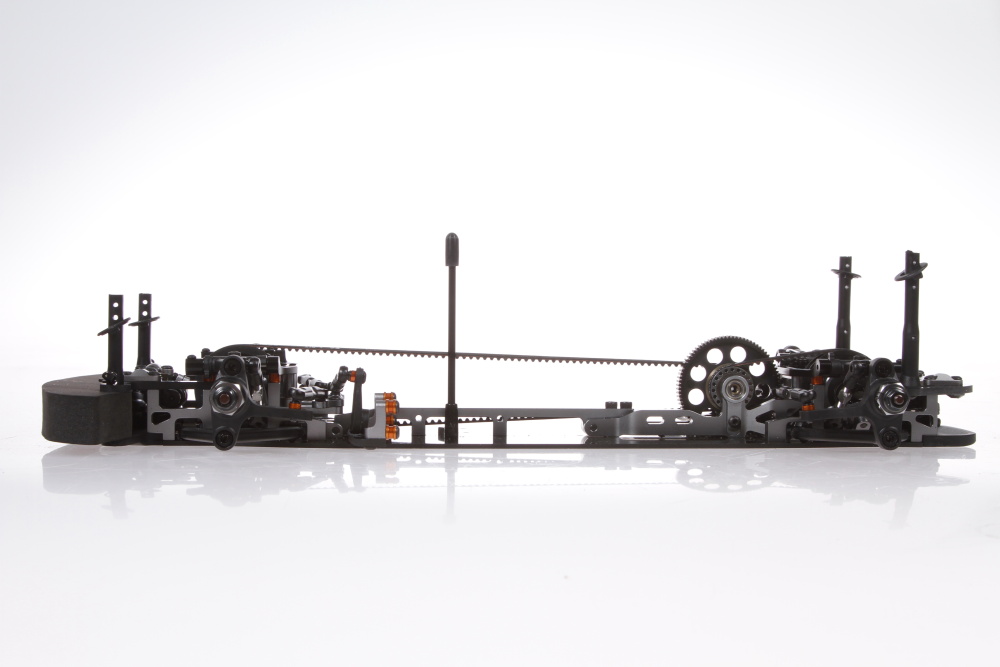

Project 4X Touringcar EP 1/10 Serpents Project 4X brand-new, revolutionary and innovative 1/10 Touringcar The Project 4X touringcar has a unique new and proven design, in which the suspensions works in a very effective different way, with an extremely low center of gravity, very easy to work on and very durable. Easy to drive and ligtning fast ! 2016-2017 IFMAR World Championship 3rd place 2016 EFRA EC A-main finalist 2016 Multiple ETS A-main finalist.

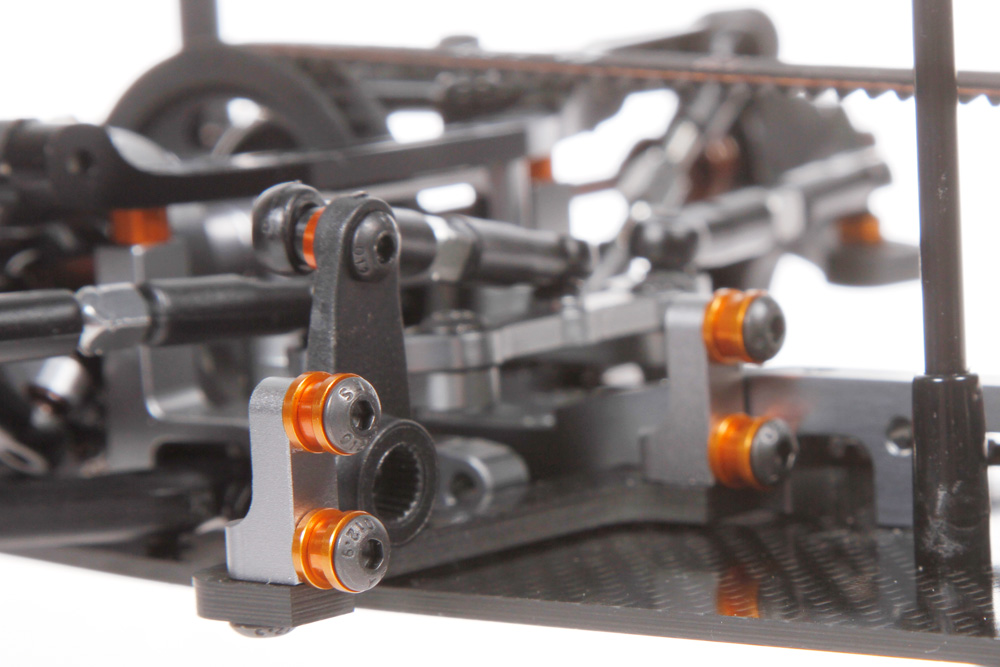

Ball-bearings

High quality, high precision lubricated longlife NSK bearings made of hardened steel throughout.

Fasteners

High quality steel fasteners for durability. Minimised number of different screws for ease of assembly and maintenance.

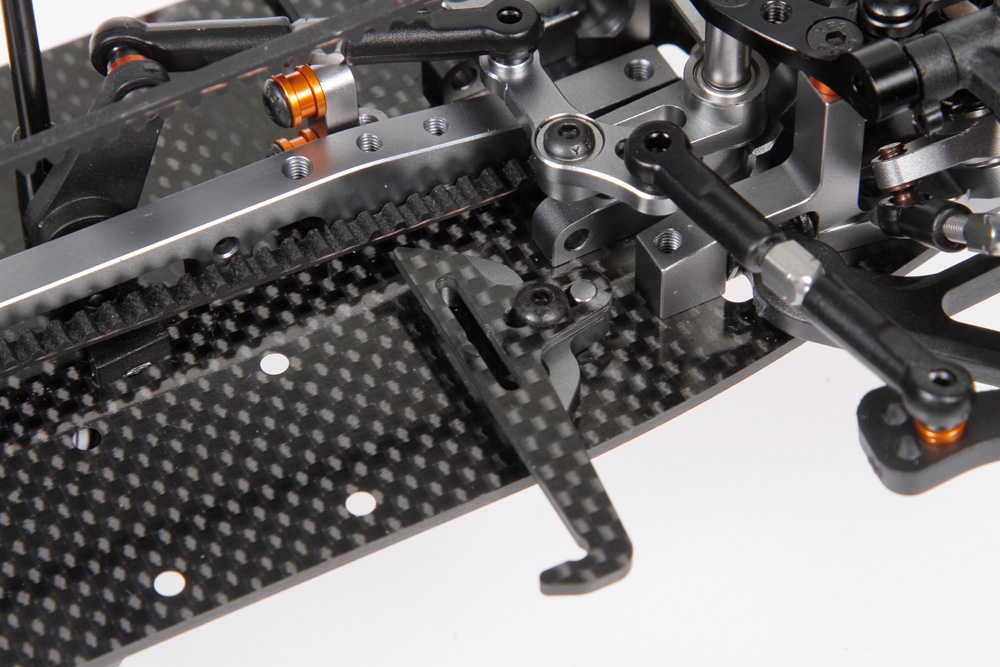

Chassis

Carbon fibre chassis in 2.0mm thickess. Countersunk holes and designed to have equal flex left to right.

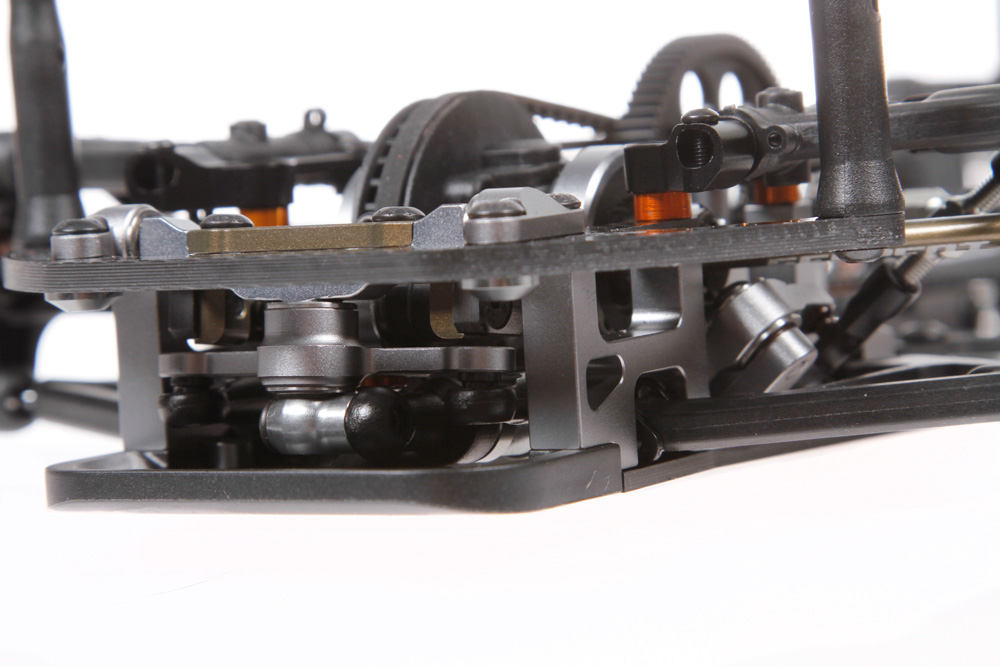

The screws to set ride height are adjusted from the bottom of the chassis with just one screw in front and one in the rear with a simple and effective mechanism to adjust the rideheight.

Battery mounts

State of the art battery mounts made in alumnium and carbon fibre and allow to position the battery more tot he front or back and secure it well in place. Shorty lipos can be placed centered, in front or rearward position.

Floating servo mount

The servomount is a combination of a carbon brace and alumnium posts. The carbon brace is bolted to the central brace and does not touch the chassis to prevent any flex influence.

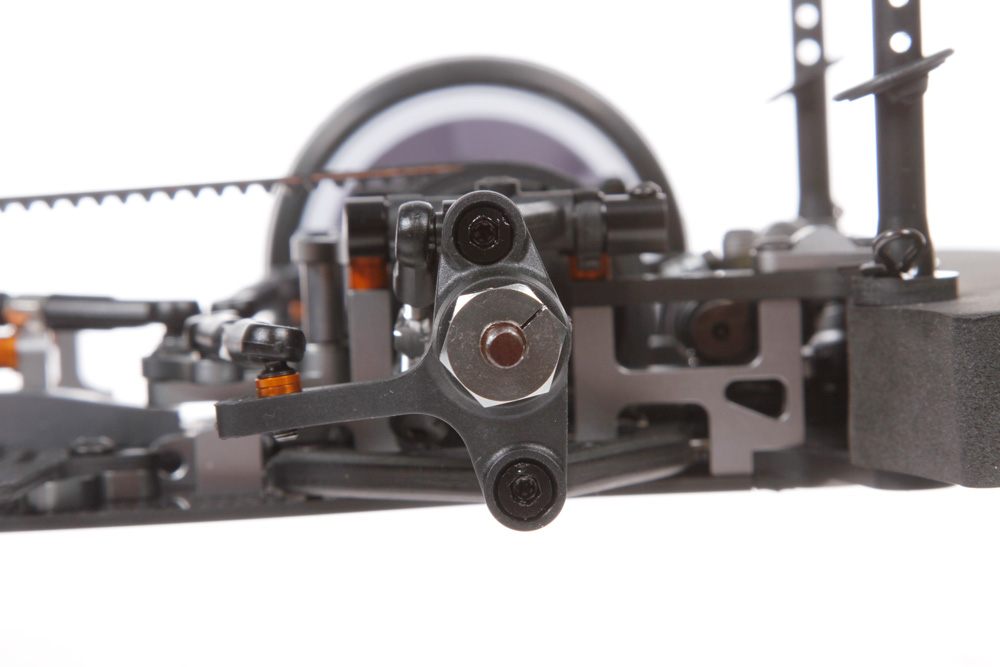

Steering system

The ballraced aluminium steering system consists of an inversed leversystem to better control the Ackermann setting. The angle difference between the inside and outside wheel is a lot more linear than in conventional designs.

Drivetrain

In the front the 4X features durable spring steel double joint cardan shafts, combined with the blade type spool.

In the rear lightweight coated aluminium cvd style dogbones are used with durable spring steel wheelaxles.

Both front and rear wheelhexes are a lightweight aluminium design

Steeringblocks / uprights

In the front and rear the same steeringblocks/uprights are in use. The pivotball system allows for easy and quick set-up changes and works very smoothly. In the front there are 3 Ackermann positions and shimming below the steeringrod can be used for fine tuning of the bumpsteer characteristics. In the rear the system allows to set Reactive Rear Steering. This RRS system allows for a change of toe-in while the suspension compresses and thus increases cornerspeed.

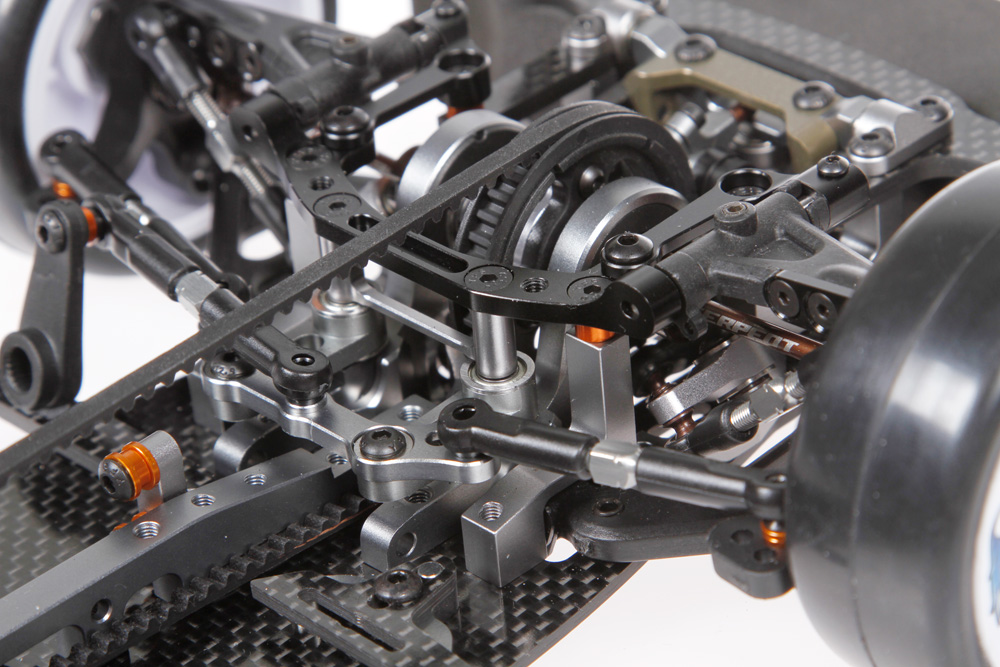

Wishbones / pullrods / rockers

The lower wishbones are the same front and rear and the same goes for the upper arms.

The lower arm mounts of 2 short pivot pins and the mounts have a lot of space to play with wheelbase by using clips. The lower arms also feature 2 downstop screws front and rear.

The upper wishbones allow quick caster changes with clips and run on an easily removable long pivot pin.

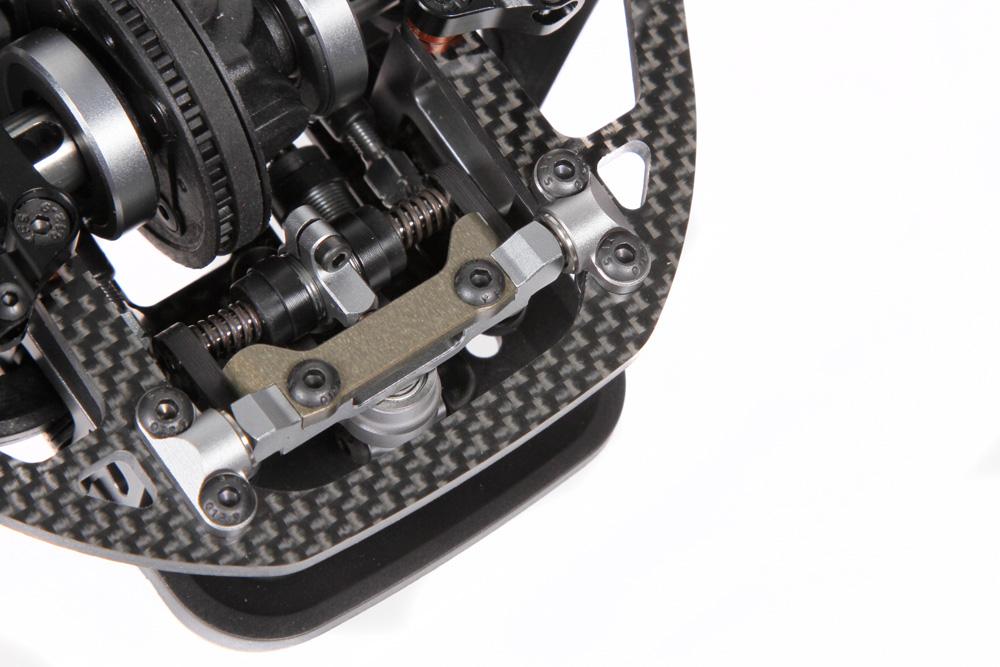

Rocker and pullrods system

The pullrods connect to the upper arms and operate the ballraced aluminium rockersystem which activates the dampening systems for heave and roll action. All trackrods and pullrods are made in coated lightweight and tough 7075 T6 alumnium.

Aluminium upper hinge pin holders and alu stiffners

The assembly is split in 2 sections to allow for easy maintenance and change of settings. The inner top brace connects both sides and creates a very strong structure preventing tweak. The topbrace is connected to the lower brackets with alu stiffners. These stiffeners can be easily removed in case more flex is needed.

The assembly rest on roll center spacers. To add additional shims for changed cambergain and rollcenter is a simple and quick setting.

Bumpers and bodymounts

In the front a strong bumper-set using a large size but light foam bumper which is sandwhiched between the lower composite bumper and upper graphite holder. The flexible moulded bodyposts with swivel-system go all through. Optional body height systems are available.

In the rear the lower bumper will prevent damage to the rear of the 4X and the moulded bodyposts with swivel system mount on a thick and stiff carbon plate, which is part of the strong rear end assembly.

Decals

The kit contains a Serpent logo decal sheet and a Project 4X logo-sheet.

Manual

The full color manual is supplied on a nice carbonlook USB stick and the latest version and updates can be downloaded from the Serpent website. The manual features an extensive assembly explanation as well as all exploded views. The exploded views are active, so when clicking a partnumber it will take you to the right partnumber in our website.

Set-ups

As set-up sheets a blank, a default and an editable pdf file is supplied and updates and set-ups from teamdrivers are online in our website, too.

Project 4X car design

The Project 4X is a unique and innovative racing car. Its very unique and different design requires the driver to take time to learn the dynamics of the car and fully understand its features. Once understood, it is not more complicated than any other racing car.

Optionals

The range of optionals for the 4X car is small as Serpent made the car toplevel racing ready.

Key optionals are the different springs used in the heave and rooll damper, the lightweight/flex chassisplate, the carbon fibre topdeck and body height adjusters.

Needed to complete the car:

Body, body paint, radio equipment, speedo, motor, tyres/wheels, battery, tools, threadlock.

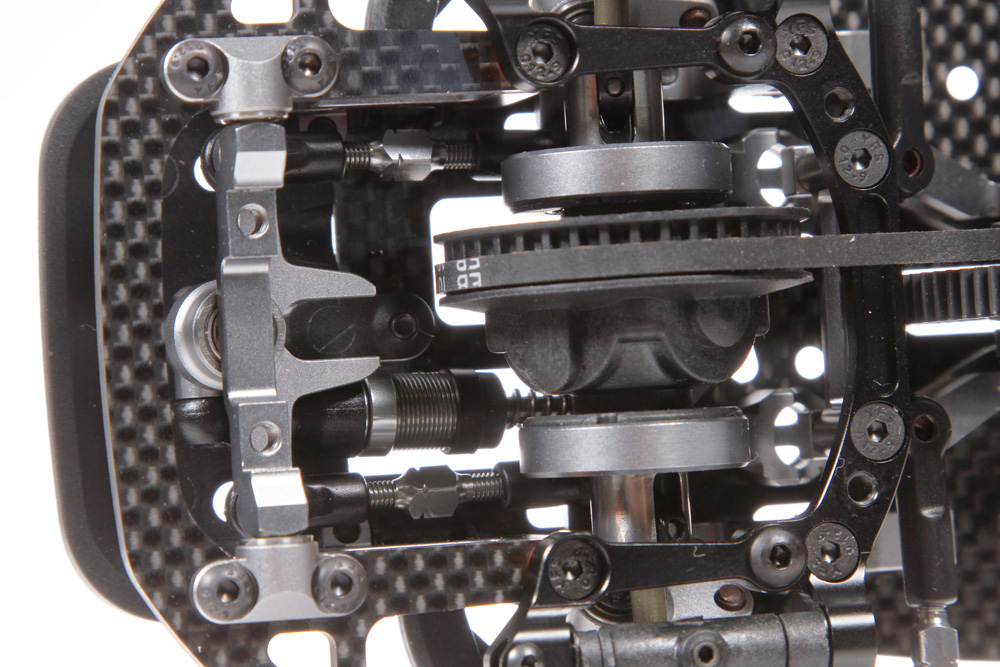

Mid shaft section

The ballraced durable hollow spring steel mid shaft holds the 2 pullies as well as the spur in place. The assembly is supereasy to build and maintain. The aluminium midshaft holder are same left and right.

Transmission

The transmission system consist of large diff and spool pullies and efficient low friction belts. The light center shaft pullies are durable coated aluminium units.

2016-2017 IFMAR World Championship 3rd place

2016 EFRA EC A-main finalist

2016 Multiple ETS A-main finalist

Key features

-Completely new suspension design system

-Separation of the roll and the heave dynamics, so these can be set-up separately for cornering and for bumps

-Very low centre of gravity

-Front and rear end share almost all parts

-Inversed steering system for better control over Ackermann angle

-Quick access and change of the damper units

-Fast and easy one-screw ride height adjustment

-Fast and easy spool and diff removal

-New spool with blades and new gear differential

-RRS system standard

IFMAR Worlds 2016 :

At the 2016 IFMAR ISTC World Championship in Beijing Viktor Wilck secured Serpent is first A final result in this class, and improve his own best result by finishing 3rd on the podium. At the World Championship 20 drivers in total were using a pre-production version of the Project 4X car to work together as a team, and at the same time do the final test.

ETS 2016:

First only in use by the factory team drivers, the 4X has finished in the A-main final of many international races including 4 times A Final at the famous ETS series

EC 2016:

a 5th place for Viktor Wilck at the European championship

Swedisch nats 2016:

Swedish Nationals title for Vikor Wilck.

During the whole testing and development program, the car was tested by top and average drivers to make sure it is not only fast but also easy to drive. The result at the IFMAR World Championship marks the perfect release date, as the car has proven to be competitive at the highest level of competition.

Serpent designer David Ehrbar and Serpent are very proud to be able to release this new innovative and high performance car to the market .

Team Serpent is using the Project 4X car for over a year now and continued to develop this very new concept. In the last ETS races Viktor Wilck was able to make the A-mains in modified at the WC, EC and ETS races and showed very good speed and consistency. Designer David has requested some more average drivers to try his car and they were amazed how easy it was to go fast.

As the car is so new and different, Serpent will spend even more time to prepare information on assembly, set-up and maintenance of the Project 4X car, in text, images and video, to help you to learn and understand the concept and unleash its full potential faster. Although at first the Project 4X car looks a bit complicated, after some explaining, you will soon understand its actually quite simple and really easy to work with. But the main advantage is that it is very easy to drive and at the same time lightning fast. Innovation Performs. The Serpent Project 4X is here!

Overview of the main specs

– Seperate roll and heave motion in the car to make set-up easier and more precise

– Roll and heave dampers are small, they need only small amounts of oil

– Dampers include machined pistons for best possible consistency

– All dampers are through rod piston systems so no membrane needed

– Good selection of heave and roll springs

– Anti-roll bar function integrated in roll damper/springs

– Easy and fast to change / replace the whole damper units

– Front and rear end are almost identical, so less spare parts needed

– Pivotball suspension for simplicity and free movement

– The Pivotballs are a lot smaller in diameter than in previous touringcars

– Easy diff and spool removal

– Extremely low center of gravity

– Reversed steering system for better Ackermann geometry

– No top deck needed (topdeck is available as optional for tough racing situations)

– Center stiffener made of 7075 T6 aluminium for rigidness and anti-tweak, connecting the front and rear end

– One piece motorholder which also connects to the center stiffener and the rear RRS system

– Re-Active rear steering RRS system is standard

– Ballraced mid-shaft holders allow easy maintenance and changing of spurgears

– Pullrod activated system with rockers to activate the dampers

– Same heave damper front and rear which is mounted below the diff/spool just above the chassis for lowest possible center of gravity

– New differential using new gears for even smoother functioning

– Battery mounting system allows reposition the battery more front or rear

– In case of shorty Lipos are used, the Lipo can be possitioned in 3 configurations

– One screw ride-height adjustment from chassis side

– Lightweight front aluminium spool with hardened steel outdrives to use blades

– Carbon fibre chassis in 2mm as standard

– DJC system in the front made out of spring-steel prevent wheelchatter and rear regular cvd is made out of 7075 T6 aluminium save weight

– One short and one longer kevlar reinforced drivebelt and supertrue running pulleys, midshaft pulleys made out of hard anodized aluminium for maximum durability

Optionals

– Carbon fibre topdeck; can be easily installed on the mounting points provided, to create a really stiff assembly. Apply in case a less aggressive and more forgiving handling is needed. Can also be tested in the 4-X without using the center stiffener, for different flex characteristic.

– Lightweight carbon fibre chassis in 2.0mm

Concept and design by Serpent Designer David Ehrbar from Germany

Specifications in detail

General

High performance 4wd touringcar with an extremely low center of gravity and a unique suspension system which seperates roll and heave set-up. This combined with a well proven transmission system and overall Serpent quality and engineering solutions.

Suspension

In the 4X car the heave and roll of the car operate and are set indepently. The front and rear end of the car are almost identical in design and share many of the same parts front and rear, so you need less different spares.

Heave damper

There is one have damper in the front and one in the rear and they work in the same way. The heave damper is located just above the chassis to lower the center of gravity. Pullrods which are connected to the upper arms link to the rocker system. The rocker system is connected through a swivel untit to the heave damper and roll damper unit. The small heave damper has a small strong shockabsorber spring and is oil filled. Different oils and springs can be used for setup work, influencing mainly bump and on-throttle/off-throttle transitions. It is easy to access from the bottom of the chassis.

The ride height is set with a simple one screw setting in the chassis, both front and rear.

Roll damper

The roll damper unit consist of an oil body for dampening with a through shaft and has a small spring on each side. This unit controls the roll of the chassis, it works as an anti-roll bar.

Different oils and springs can be used for setup work. The whole unit comes out after releasing just 2 screws. One can have complete rolldamper assemblies ready to change settings in seconds.

Chassis stiffner

The 7075 T6 central alu brace takes care of the connection between front and rear end and prevents unwanted tweak and takes care of torsional stress. For most situations it eliminates the need of a topdeck.

Motor mount

Extremely low 7075 T6 aluminium motormount which doubles up as connector for the midshaft holders, connection for the RRS system, holder for the alu stiffner and conector to the central brace, all-in one.

Gear differential

The nicely shaped renewed gear differential features new internal gears which makes it supersmooth. The compact and light unit holds a good amount of oil to deliver stabile performance throughout the run. It is fast and easy to take out and re-mount the differential.

Front spool

The coated aluminium front spool with lightened springsteel outdrives is a blade type which ensures superb handling and durability throughout the race, and it is easy to exchange blades as needed. It is fast and easy to take out and re-mount the spool. The springsteel is strong enough that you can easily finish your run even with a broken blade without damaging the outdrives too much.

Concept and design by Serpent Designer David Ehrbar from Germany

2016-2017 IFMAR World Championship 3rd place

2016 EFRA EC A-main finalist

2016 Multiple ETS A-main finalist